Introducing CERIA Set: Your Artificial Intelligence Printing Optimization Solution

When it comes to 3D printing technical ceramics, efficiency is crucial. Making the most of your resources and minimizing waste are key factors for success. Enter CERIA Set – our artificial intelligence software designed to enhance your printing processes.

How does CERIA Set artificial intelligence software optimize 3D printing?

CERIA Set offers three main features:

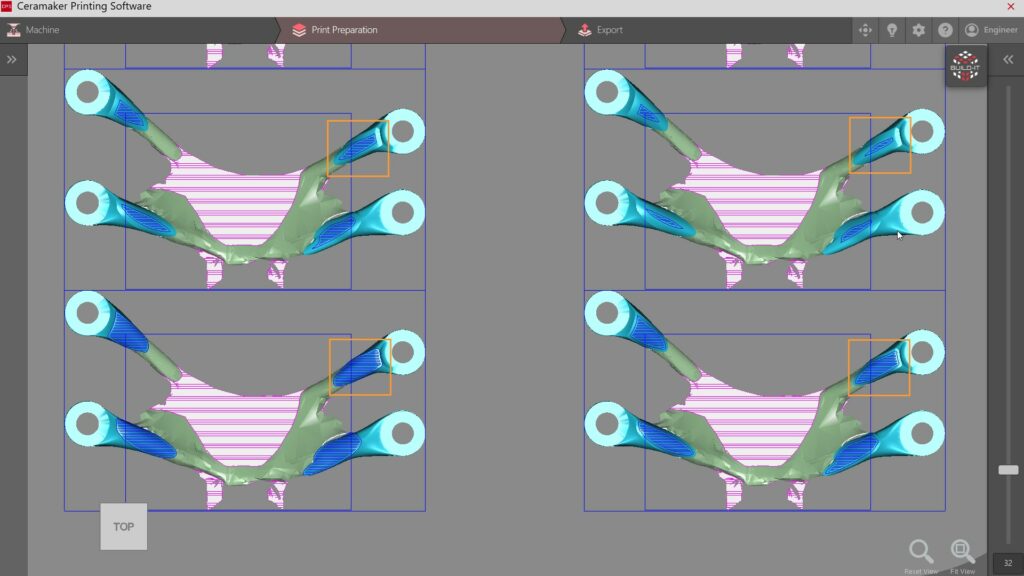

- Assistance with part conception and precise placement within the tank

- Thorough analysis of the final tank configuration for optimal results

- Tailored and optimized scraping parameters to ensure flawless prints

Optimized 3D printing with CERIA: reduced waste and simplified printing experience

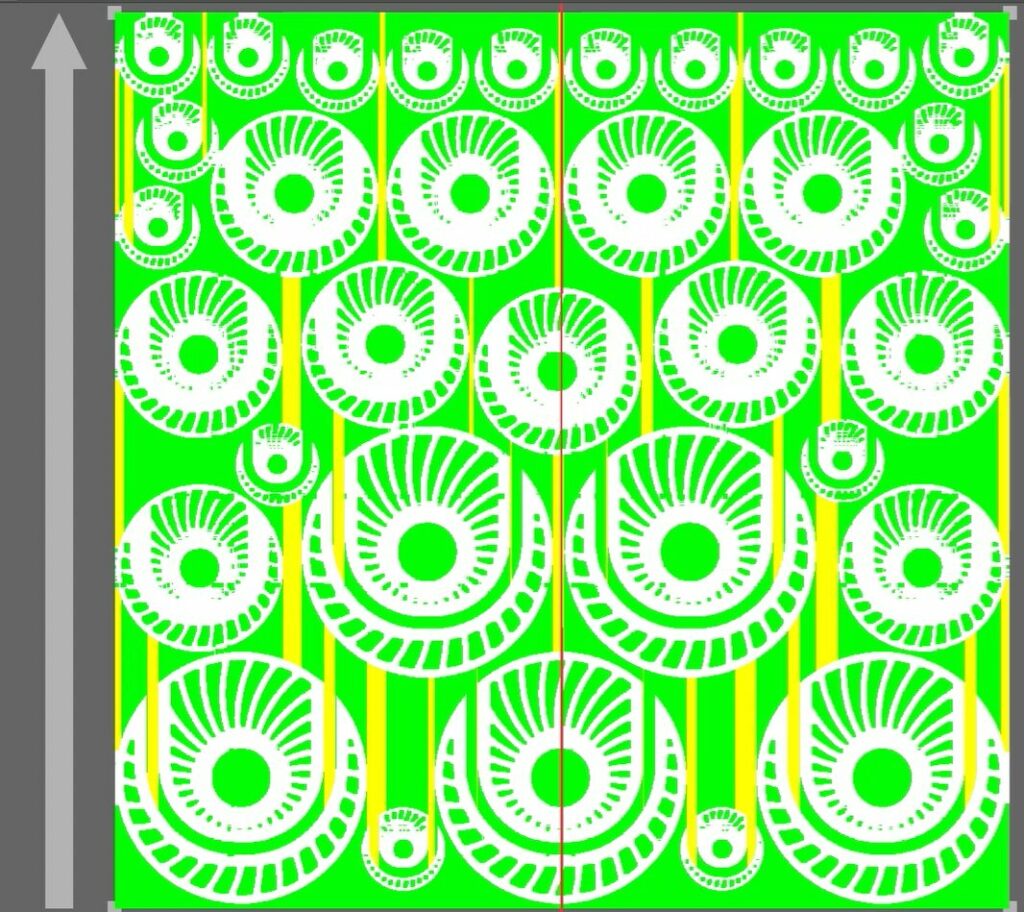

- Simplified experience: Designed with simplicity in mind, CERIA Set eliminates complexity and reduces the error rate in your prints by anticipating part design faults in its geometric structure. In fact, Ceria Set enables you to comply with the design rules inherent in 3D printing. Ceria Set also assists you in the design of your printing tanks, highlighting the spaces to be occupied, the layout of parts, etc. Ceria Set's functions and user-friendly interface make the printing process smooth and efficient.

- Ceria Set carefully analyzes your print files to identify potential problems (empty spaces, sizing errors, etc.) that could hinder the printing cycle. In this way, you can save both material and time, while increasing your success rate.

How to integrate Ceria Set artificial intelligence

CERIA Set is a 3DCeram exclusive developed in-house by our teams and our artificial intelligence experts. It complements our two other software products: Build-It and CPS 2.0.

Now, let's explore the intricacies of CERIA's functionality:

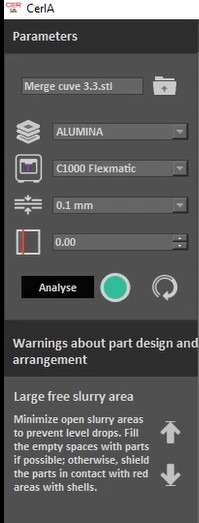

- Analytical insights: After downloading your print files, CERIA Set performs a meticulous analysis that highlights areas for improvement. With simple messages and recommendations, CERIA Set guides you to optimized printing results.

- Detection of areas prone to excess material: CERIA Set detects empty spaces, ensuring efficient use of materials and minimizing waste.

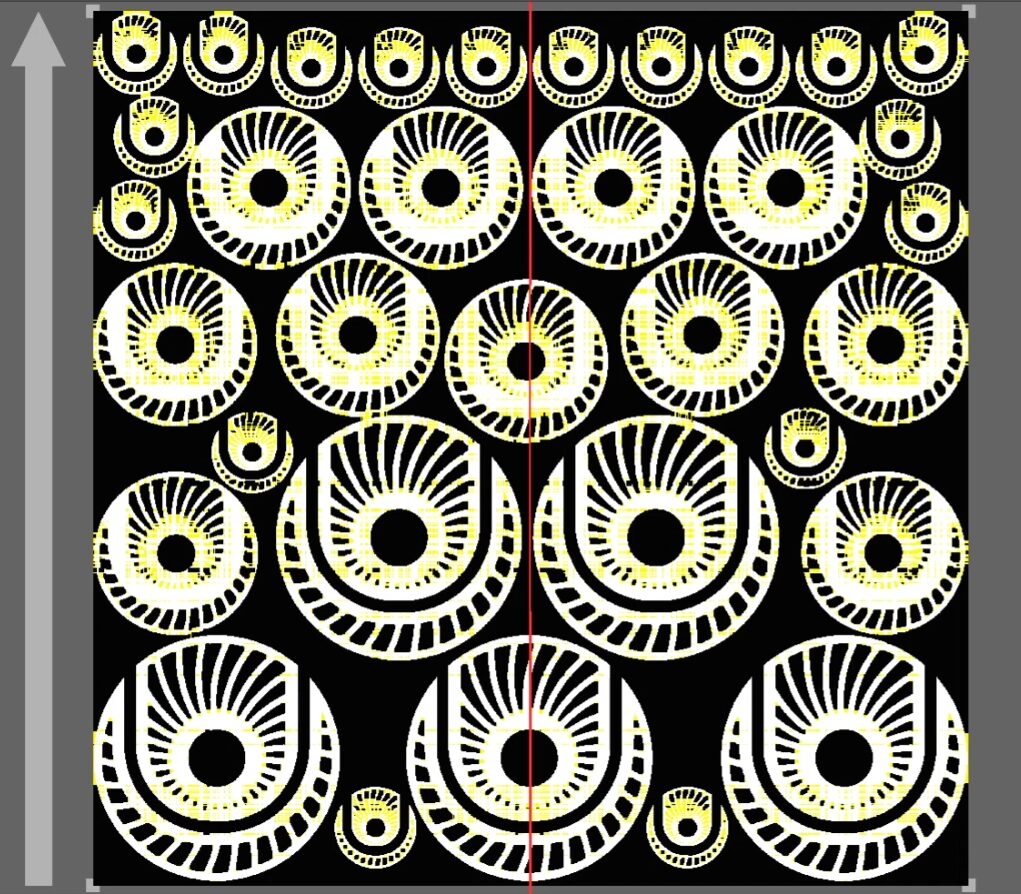

- Visualization tool: Check the progress of your part file layer by layer, thanks to CERIA Set's intuitive color-coding system. Visual cues simplify the printing process, from design to completion. White represents your part, yellow indicates fixed slurry zones and red potential slurry leaks.

CERIA Set available on our industrial printers

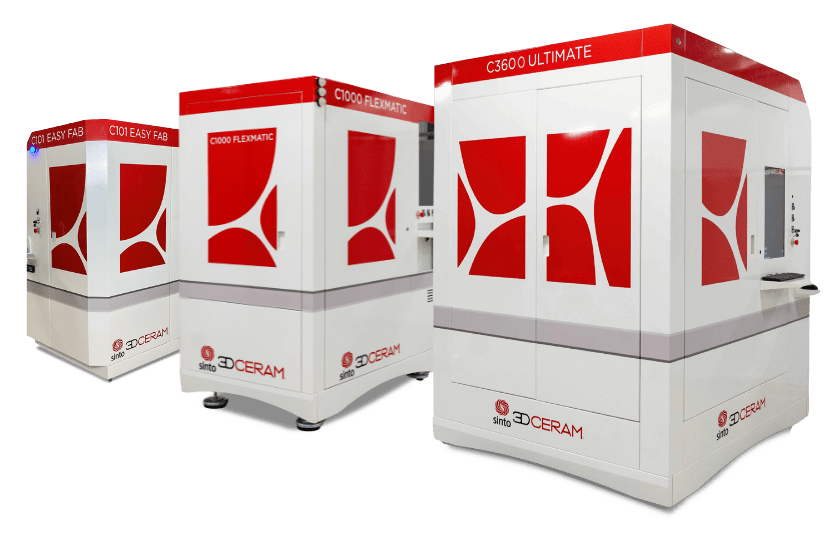

CERIA Set is specifically tailored to industrial needs, making it a must-have on C101 EASY FAB, C1000 FLEXMATIC and C3601 models.

In conclusion, CERIA Set is not just a tool - it's a practical solution that is the fruit of 3DCeram's 20 years' experience in the research and development of 3D printing solutions for technical ceramics. Thanks to its advanced features and user-friendly design, CERIA Set enables users and manufacturers to improve their printing efficiency and derive maximum benefit from additive manufacturing. This is a major step forward, which is sure to accelerate the adoption of 3D printing by leading manufacturers looking for a reliable and productive process.

CERIA Set heralds a new era in 3D printing.