The landscape of 3D printing evolves, with technology constantly being pushed to new frontiers. The most exciting developments in this space is definitely the Artificial Intelligence. At the forefront, CERIA, the artificial intelligence (AI) developed by 3DCeram, to optimize the ceramic 3D printing to reach the industrial scale! As industries like aerospace, medical devices, and automotive continue to rely on the precision and versatility of 3D printing, CERIA is offering a smarter, and more efficient approach to design and production.

The core innovation behind CERIA is its ability to leverage AI to improve the ceramic 3D printing process. Traditional 3D printing often involves some manual adjustments and trial or iterations to get designs and printing parameters just right. With CERIA, the AI automatically analyzes and optimizes designs, streamlining productions, and reducing the production costly.

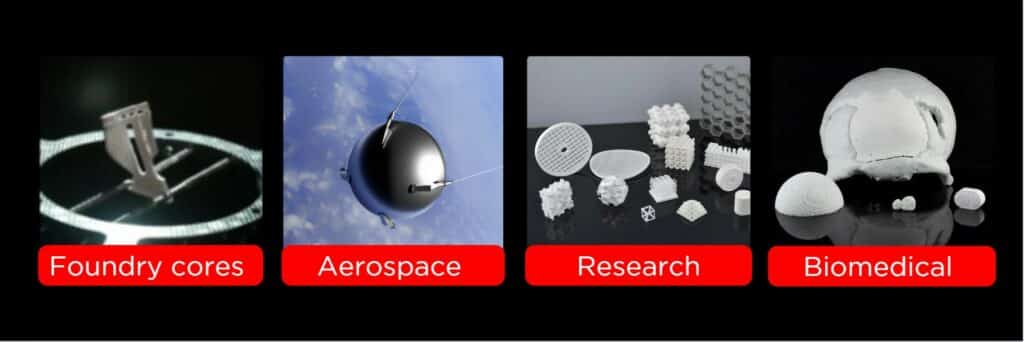

This is particularly useful in industries where precision is paramount. For instance, aerospace components must adhere to strict standards for weight and strength, while medical devices need to be produced with an extraordinary level of detail. By utilizing CERIA, the AI, helps manufacturers meet these demands with far greater efficiency than traditional methods.

One of CERIA’s standout features is its real-time monitoring capabilities. As a 3D print progresses, CERIA tracks and analyzes the 3 printed layers, adjusting parameters in real time to maintain the highest level of quality on the next 5 layers to come. This feature helps manufacturers catch any potential issues early in the process, before they happen and then will waste time and materials.

By ensuring that each layer is printed with the utmost accuracy, CERIA adapts the right material quantity needed and contributes to a more sustainable production process. This feature is particularly important for industries that use expensive, specialized materials for their products, such as ceramics used in aerospace or medical applications.

For companies already invested in 3DCeram’s tools, CERIA integrates smoothly with the other softwares like Build-It and CPS 2.0, creating a comprehensive workflow that extends from design to production. This integration simplifies the process.

CERIA's versatility makes it a valuable tool for various industries. In the aerospace sector, for example, CERIA helps streamline the production of lightweight, high-performance parts. Its ability to optimize material usage and ensure precision in design is crucial for creating components that meet the rigorous demands of aviation and space technology.

For the semiconductor industry, which is a strategic application, CERIA optimizes the success and production costs of large components such as suction plates with internal channels,and end effectors that require extreme precision.

The medical industry benefits from CERIA’s capability to print highly detailed, customized implants and surgical tools. With the help of AI-driven optimizations, manufacturers can produce parts with the exact specifications needed for patient-specific solutions, all while ensuring the necessary levels of safety and reliability.

Automotive manufacturers also stand to gain from CERIA’s ability to improve production efficiency and reduce costs. By minimizing material use and enhancing print speed and quality, CERIA enables companies to produce parts that meet performance requirements at the right rate of costs.

As the capabilities of AI and 3D printing continue to evolve, CERIA is positioned to play a pivotal role in the future of ceramic manufacturing. By combining the precision of 3D printing with the AI, CERIA offers manufacturers a more efficient, cost-effective way to produce high-quality ceramic parts. CERIA not only improves the design process but also accelerates production, making it an essential tool for industries that require both speed and precision.

In an increasingly competitive market, CERIA’s ability to reduce material use, improve production speed, and maintain high-quality standards makes it a key game changer for the future of 3D printing. As more industries look to adopt 3D printing for complex applications, CERIA is setting the stage for a new era of smarter, more sustainable manufacturing.

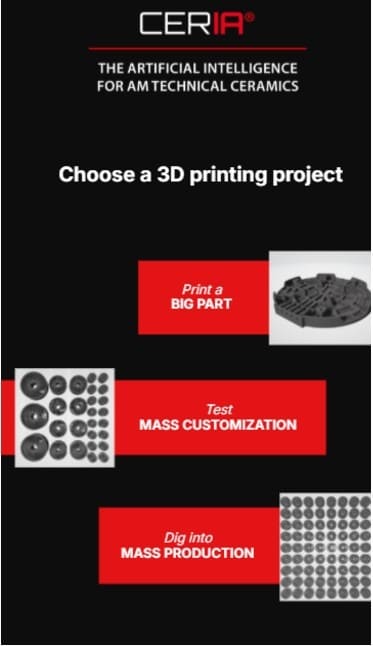

To help users fully grasp the potential of Ceria, we launched an interactive quizz game at Formnext 2024, allowing attendees to experience firsthand how the IA can optimize their 3D printing projects. The game demonstrates CERIA's capabilities by showcasing several distinct scenarios: printing a series of small parts and printing a large part in one single run.

This hands-on approach allowed participants to see how CERIA's AI can dynamically adjust parameters and optimize production, whether it’s managing the complexities of small parts or handling the challenges of larger parts in a single print. The game provided a fun and interactive way for visitors to explore how the software could benefit their own work, regardless of the size or scale of their projects.

Now, for those who weren’t able to attend Formnext, we’re excited to offer this interactive experience online. You can explore CERIA and understand how it can optimize your own projects, whether you’re working with small, detailed parts or large, complex components. Try it yourself and see how Ceria can elevate your 3D printing process.

Now, you can try it for yourself and explore the power of Ceria to streamline your 3D printing processes!

We hope this article has been helpful and provided you with valuable information. If you have any questions, want to discuss your project, or need personalized advice, don’t hesitate to get in touch. Click the button below to schedule a call with one of our experts.