The C1000 FLEXMATIC is a fully industrial ceramic 3D printing system engineered to meet manufacturers’ expectations in terms of productivity, repeatability, and profitable production costs.

The C1000 FLEXMATIC is designed to integrate seamlessly into semi-automated production lines, significantly reducing manual operations, process variability, and overall cost per part.

By combining advanced automation with CERIA, 3DCeram Sinto’s in-house developed Artificial Intelligence, the system enables fast setup, secure operation, and stable process control—making ceramic additive manufacturing accessible beyond expert users while maintaining industrial-grade performance.

A platform that meets theneeds for versatility:

- large parts and series of parts

- 320*320*200 mm;

- A removable tank that allows the in-line processing of printed parts.

- User-friendly, no engineering skills required to start a printing run.

- Automation of the recycling process : uncured material and automatic cleaning step.

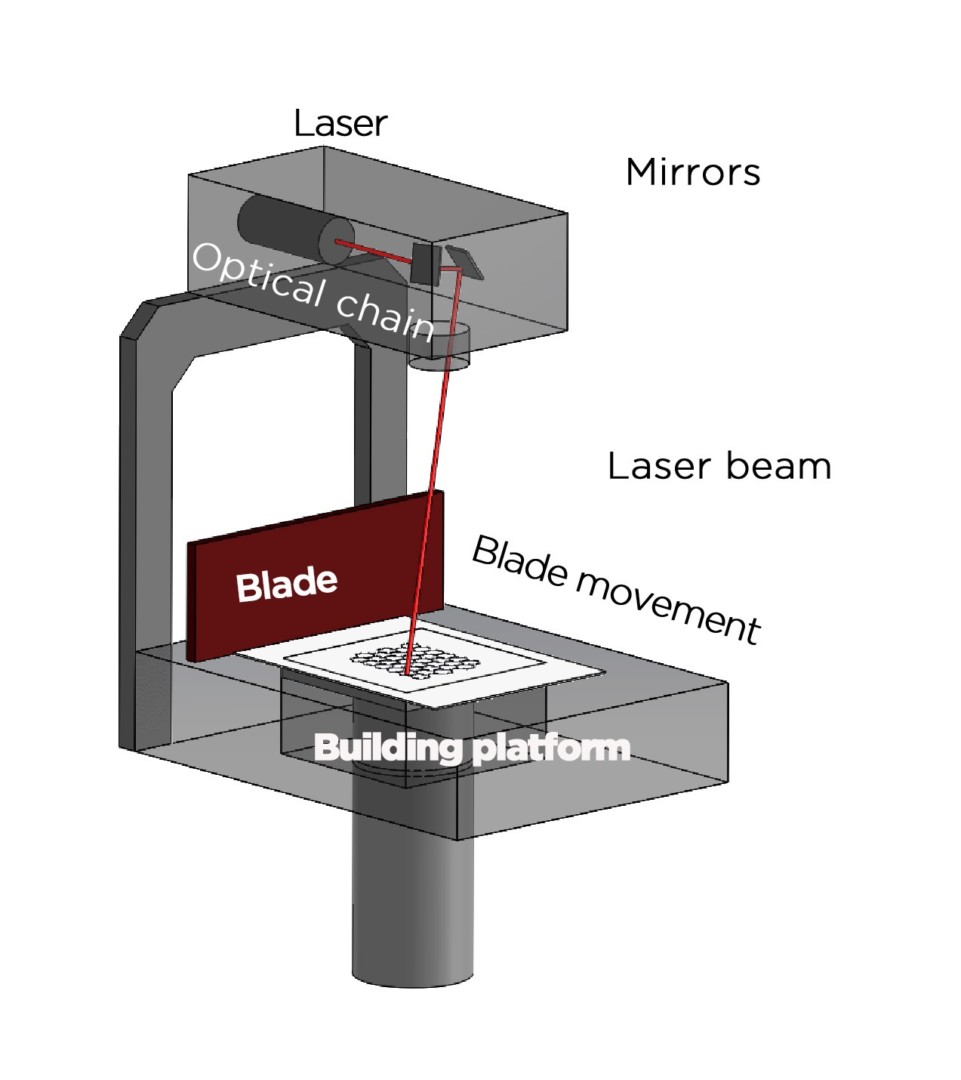

Top-down stereolithography enables technology that can print without supports. The tray moves down as the part itself is built from the bottom-up. 3DCeram is able produce consistent parts with high precision and fine details.

The feeding of the printing material is done by a printing material is fed into a cartridge which is simply filled at the beginning of the printing cycle. It is possible to re-fill the cartridge during the printing cycle.