• User friendly

• Lab Mode for free development

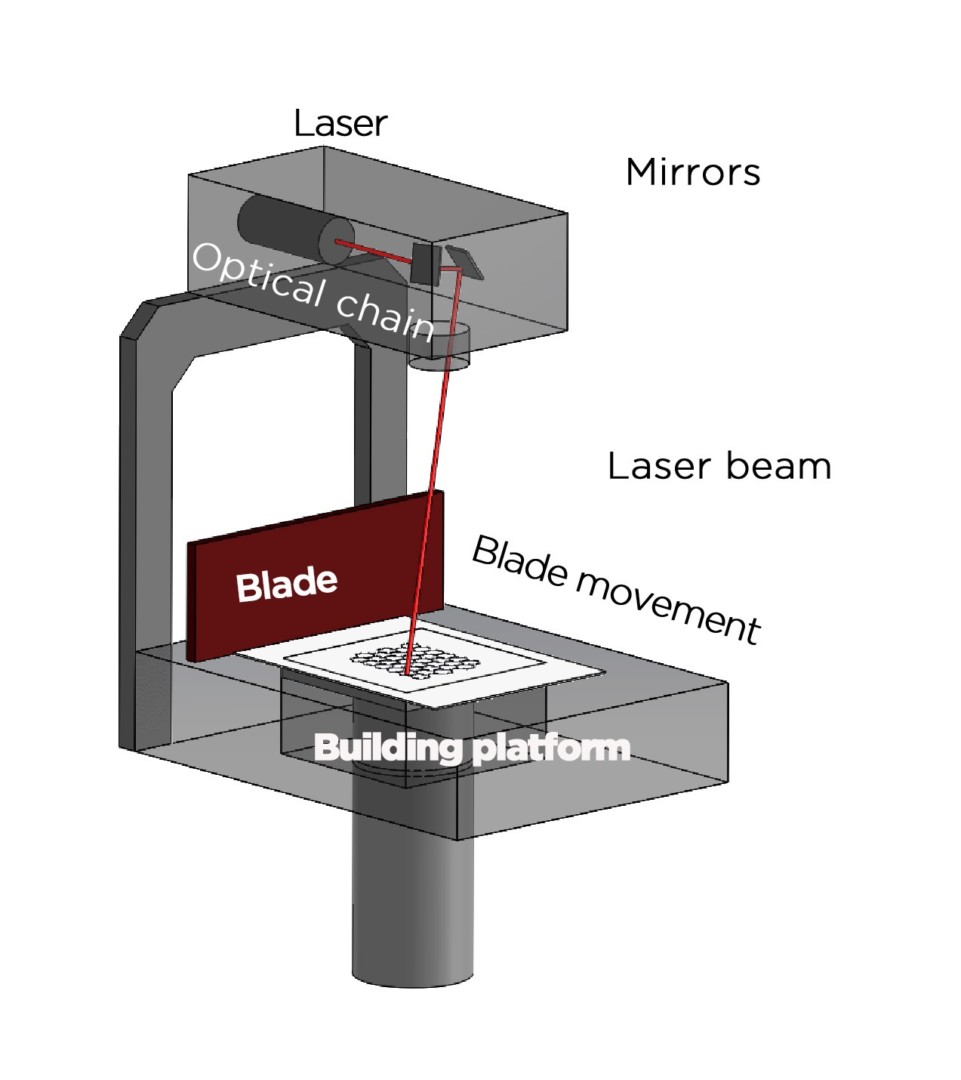

• Stereolithography laser

• Optimized accessibility

• A pressure tank (2,5 liter) feeding to provide the material quantity required for an optimized run 100*100*150

• Accurate control of the quantity of slurry thanks to the peristaltic pump, automatic adjustment of slurry quantity dispensed

• Accessible for persons with reduced mobility

• Easy scale up to C3601 (600 x 600 x 300 mm)

Top-down stereolithography enables technology that can print without supports. The tray moves down as the part itself is built from the bottom-up. 3DCeram is able produce consistent parts with high precision and fine details.

The feeding of the printing material is done by a printing material is fed into a cartridge which is simply filled at the beginning of the printing cycle. It is possible to re-fill the cartridge during the printing cycle.