• Printer dedicated to research centers and universities for research and development

• Easy to use

• Optimized accessibility

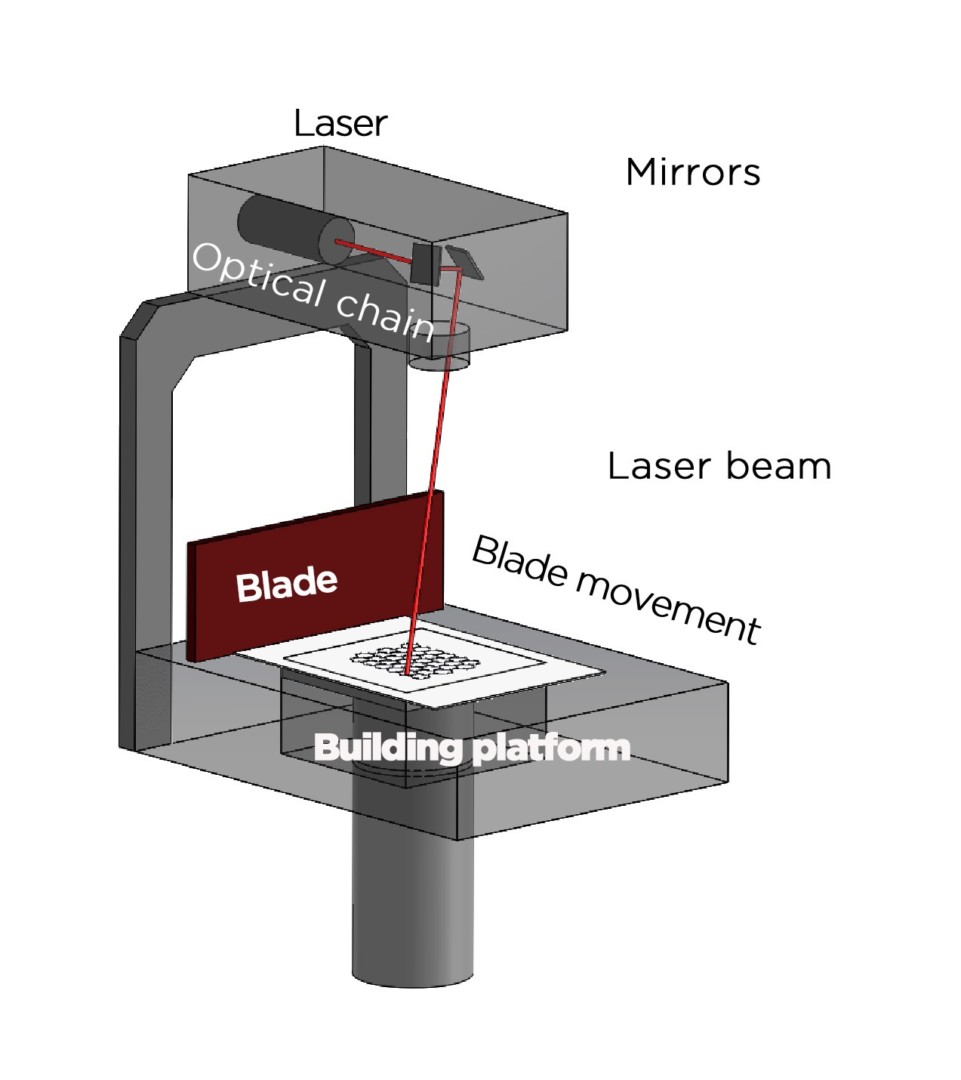

• Stereolithography (Laser)

• Open parameters

• Printing with the right amount of ceramic

• Optimization of the printing precision elements (mechanical and optical)

• Accessible to people with reduced mobility

• 60 mL of ceramic is enough to start a print or 10 mL with the SAM (Small Amount of Material) option

• 180 mL, 360 mL, 600 mL and 920 mL cartridges available

Top-down stereolithography enables technology that can print without supports. The tray moves down as the part itself is built from the bottom-up. 3DCeram is able produce consistent parts with high precision and fine details.

The feeding of the printing material is done by a printing material is fed into a cartridge which is simply filled at the beginning of the printing cycle. It is possible to re-fill the cartridge during the printing cycle.