In a groundbreaking webinar hosted by 3Dnatives, Maxence Bourjol, Head of Sales at 3DCeram, and Johannes Noll, Development Engineer at Bosch Advanced Ceramics, explored the revolutionary capabilities of laser-based ceramic additive manufacturing for producing large-scale, high-performance ceramics in series production.

This insightful session highlighted how this cutting-edge technology is transforming industries such as aerospace, semiconductor, and beyond, and its potential to redefine high-precision ceramic manufacturing.

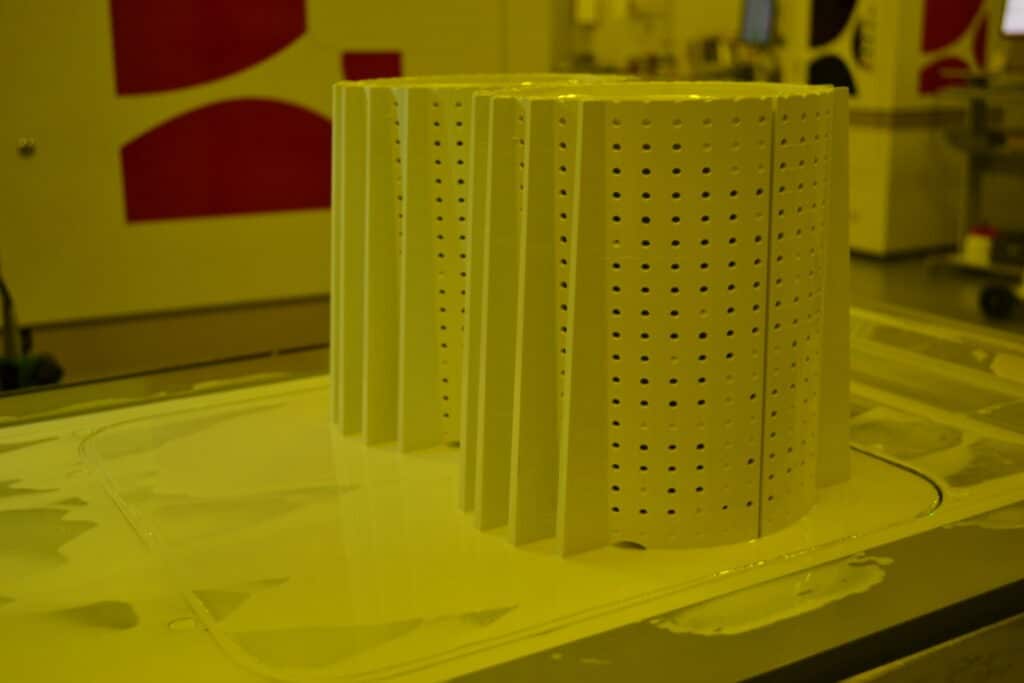

Laser-based additive manufacturing is fundamentally changing the way high-precision ceramic parts are produced. This technology allows manufacturers to achieve unparalleled flexibility in design and scalability while maintaining the unique material properties of ceramics, such as high temperature resistance, hardness, and corrosion resistance.

Maxence Bourjol and Johannes Noll shared real-world applications demonstrating how laser-based printing is enabling industries to meet the growing demand for complex, high-performance ceramic components essential in high-stress environments.

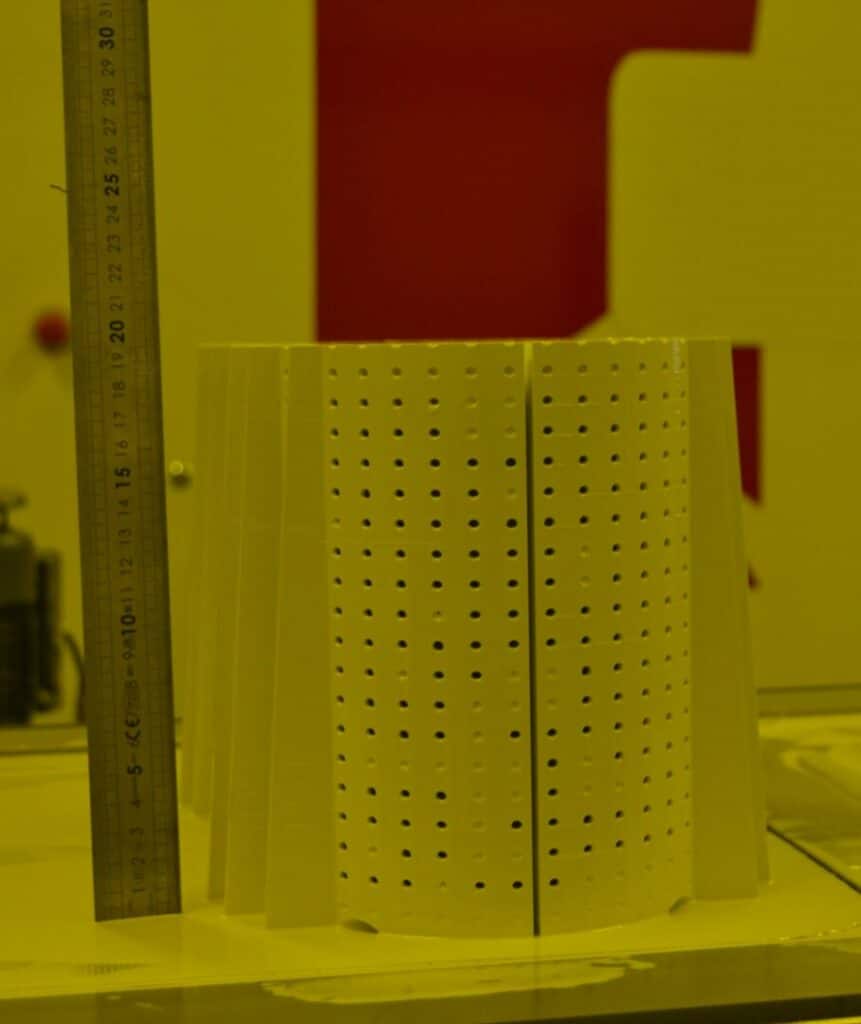

The webinar focused on the critical technological requirements for success in laser-based ceramic additive manufacturing. Experts from 3DCeram and Bosch emphasized the importance of precise control over laser parameters, material formulations, and post-processing techniques to achieve high-quality ceramics that meet rigorous industry standards.

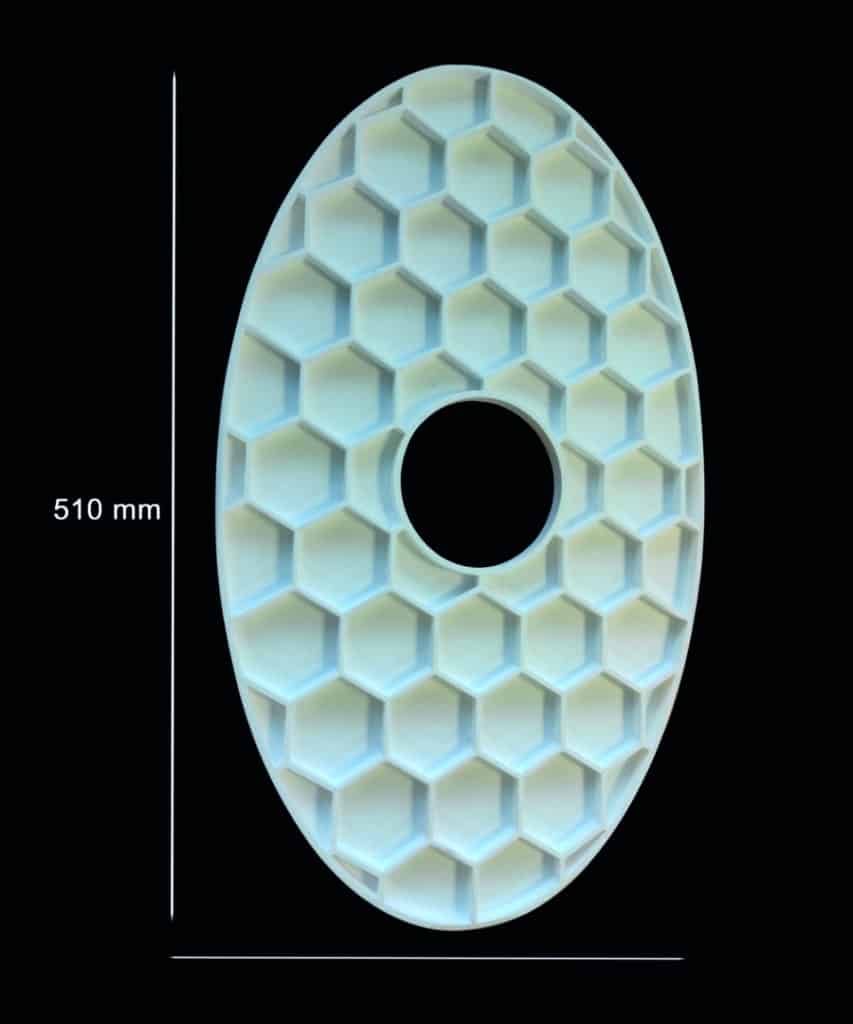

For industries like aerospace, where components must withstand extreme conditions, this technology opens the door to producing lightweight yet durable ceramic parts that would otherwise be challenging to create using traditional methods.

A key highlight of the webinar was the application of laser-based ceramic printing in aerospace and semiconductor industries. In aerospace, the ability to produce lightweight and thermally resistant ceramic components using 3D printing is transforming the design and production of critical parts such as turbine blades and nozzles.

Similarly, in the semiconductor industry, laser-based ceramics offer enhanced precision and reliability, key factors for the performance of next-generation technology.

At the forefront of these innovations is 3DCeram’s advanced SLA (Stereolithography) technology, which allows for precise layer-by-layer fabrication of complex ceramic structures.

By integrating laser printing capabilities with optimized material formulations and advanced process control, 3DCeram is helping industries push the limits of ceramic component production.

If you missed the live session or want to revisit the valuable insights shared, the full webinar is now available for on-demand viewing. It’s your chance to dive deep into the future of laser-based ceramic 3D printing and how it’s set to revolutionize industries that rely on high-performance ceramics.

🚀 Whether you’re in aerospace, semiconductor, or another industry that relies on cutting-edge materials, this webinar is a must-watch. Get inspired and discover how you can be part of the next wave of industrial innovation!