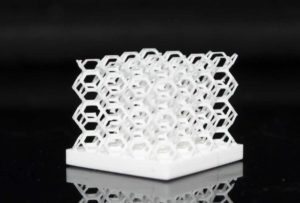

When it comes to 3D printing technical ceramics, efficiency is crucial. Making the most of your resources and minimizing waste are key factors for success. Enter CERIA Set – our artificial intelligence software designed to enhance your printing processes. How does CERIA Set artificial intelligence software optimize 3D printing? CERIA Set offers three main features: Optimized 3D printing with CERIA: reduced waste and simplified printing experience How to integrate Ceria […]