3D Printing is pushing the boundaries of the biomedical field, and the latest Young Ceramists Network (YCN) webinar provided an in-depth look at the cutting-edge advancements in 3D-printed implants. Charlie Clark, an expert from 3DCeram, shared valuable insights into the transformative potential of ceramic additive manufacturing for medical applications.

🔗 Watch the full webinar here: YCN #19 - 3D Printing in Biomedical applications

Since 2005, 3DCeram has been at the forefront of 3D-printed medical implants, with more than 15 custom skull implants successfully completed for patients at the CHU de Limoges. This webinar explored the advantages of 3D printing in cranial reconstruction, highlighting the ability to create implants with varying densities to optimize mechanical strength, osteointegration, and surgical fixation. Real-world cases demonstrated how these customized implants seamlessly integrate with bone structure, improving patient outcomes.

The session also covered groundbreaking research conducted in collaboration with INSA Lyon on cerium-stabilized zirconia. This innovative ceramic material significantly improves the longevity of biomedical implants by addressing aging-related degradation, which has been a major challenge in traditional zirconia implants. The research aims to enhance the mechanical properties and durability of implants, potentially eliminating the need for revision surgeries.

Click down below to watch an interview about our collaboration with the surgeon we worked with to use the first skull implants on real life cases :

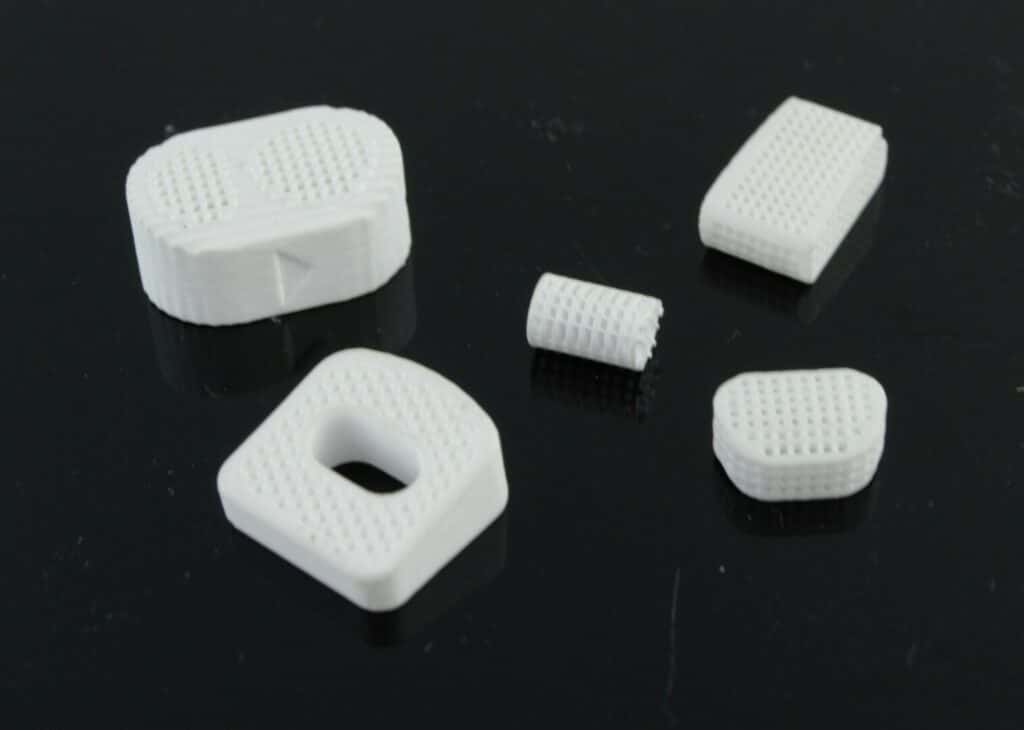

Another key highlight was the collaboration between 3DCeram and a customer in Australia to develop next-generation spinal cages using a novel strontium-based ceramic material. Traditionally, spinal cages require bone grafting, leading to additional surgical procedures. This new material not only enhances bioactivity and bone fusion but also has the potential to eliminate the need for autografts, simplifying spinal surgery and improving patient recovery.

Charlie Clark also detailed the unique benefits of SLA (Stereolithography) technology used by 3DCeram. This top-down approach enables precise layer-by-layer fabrication, allowing the production of intricate lattice structures that enhance biocompatibility and mechanical performance. The combination of advanced formulations, optimized printing parameters, and post-processing techniques ensures that ceramic implants meet the highest industry standards, with examples that speak for themselves.

For those interested in learning more about these groundbreaking innovations in biomedical 3D printing, the full webinar is available on our YouTube channel. Discover how ceramic additive manufacturing is pushing the boundaries of medical technology and shaping the future of personalized healthcare.