22 octobre 2018

22 October 2018. Back in November 2016, the partnership between 3DCeram Sinto and Creatz3D facilitated the installation of 3DCeram Sinto’s Ceramaker 900 Ceramic 3D printer at Advanced Remanufacturing Technology Centre, in Singapore, and pooled together both companies’ years of additive manufacturing expertise.

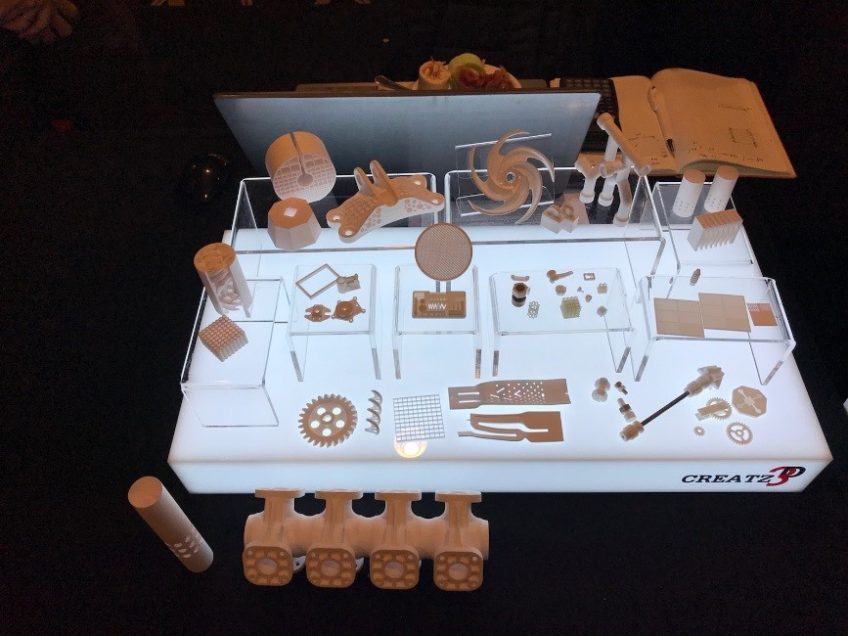

Formed in 2017 as a subdivision of its parent company, Creatz3D, Creatz3D Ceramics Service Bureau is dedicated to the 3D printing of ceramics parts. Creatz3D is a Singaporean company that was founded in 2012 and is an authorized reseller of professional industrial-grade 3D printers, additive manufacturing software solutions, and polishing systems.

Having an extensive installed base of more than 150, Creatz3D has accumulated years of expertise and experience in the 3D printing industry, hailing from diverse sectors such as manufacturing, aerospace, automotive, consumer goods & electronics, toys, medical, education, animation, and many more.

In recent years, there has been a concerted push by the Singapore government in promoting additive manufacturing adoption in light of the Industry 4.0 movement, but the applicability of ceramics AM is still unknown due to its positioning unlike matured technologies like plastics and metals.

With the expertise and knowledge of 3DCeram Sinto in technical ceramics printing, the collaboration has allowed Creatz3D to push its boundaries through research and development of new applications, to accelerate the adoption of ceramics AM in Singapore.

The Creatz3D Ceramics website was officially launched in July 2018, which represented a significant step towards being a full-fledged service bureau in providing quality ceramics 3D printing services.

Advantages of employing Creatz3D Ceramics Service Bureau:

• Diverse material options – varied applications with better compatibility and applicability thanks to the large possibilities of 3DMIX paste (zirconia, alumina, silica, silicon nitride, HAP, TCP, ZTA, cordierite)

• Specialized ceramic 3D printing services

• Utilizes state-of-the-art technology to cater to desired requirements

• Hassle-free experience, be it customization or optimization of 3D printing parts.

Testimony of Sean Looi, General Manager of Creatz3D

System integration is always the first priority for customers and extensive market research showed that 3DCeram had a significant advantage over others, with their over 10 years of progressive experience in ceramics additive manufacturing. Their turnkey system especially stood out with tight integration between their Ceramaker ceramic printing technology, 3DMIX pastes, and personalized support capabilities.

The addition of ceramics to Creatz3D’s portfolio ensures that they stay ahead of the pack in the competitive 3D printing landscape, and their expertise can demonstrate the game-changing capabilities that the technology has to offer to help advance design, engineering, and manufacturing.

With the additive manufacturing industry calling out for alternative material options, the opportunities and market potential for ceramics could be transformative given how they possess certain unique characteristics. The Ceramaker system is the first of its kind in Singapore and Creatz3D is extensively involved in the research of ceramics 3D printing possibilities to drive, prove, and provide industry to not only users and companies in Singapore, but with an eye to go global in time to come.

The Ceramaker 900 has performed consistently since its installation and churns out Alumina and Zirconia ceramic 3D printed parts reliably. Despite its label as a production machine, the variety of platform sizes affords flexibility when it comes to choosing the platform. This is particularly useful during machine operations as it minimizes material loading and the overall printing time.

Customers who have relied on Creatz3D to do service printing using the Ceramaker 900, were notably impressed with the surface quality of the 3D printed ceramic parts they had received.

Apart from the consistent quality of the produced parts, the Ceramaker 900 has also been highly reliable for almost a year since the last on-site maintenance by 3DCeram engineers. The training provided by 3DCeram Sinto also allowed Creatz3D engineers to operate the machines confidently but also trained them in optimization to achieve high-quality ceramic parts. The training and support provided by 3DCeram Sinto are thus critical in helping Creatz3D meet the demands of customers.

As the first installation in Singapore, it represents a significant milestone for not only 3DCeram but also Creatz3D as awareness of the suitability of technical ceramics for 3D printing applications grow.