The medical sector has always been interested in cutting-edge technologies, which is why 3DCeram has been working with biomedical players since 2005. For more than 15 years 3D printing has continued its development to offer today a level of maturity that can now meet the requirements of the biomedical field.

Additive manufacturing for ceramic is ready to integrate the supply chain of the medical field.

3DCeram has developed its mastery of 3D printing ceramics process, its machines, materials and services as maintenance and trainings. The large range of printers from C100 EASY FAB to C3600 ULTIMATE, depending on production capacity requirements for biomedical devices or dental.

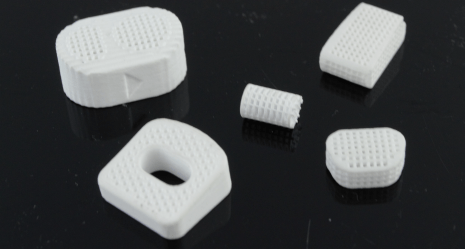

On the other hand, specific formulations have been developed over the years for osteointegration and biocompatibility, like HAP (Hydroxyapatite) or TCP (Tricalcium Phosphate) or Alumina Toughened Zirconia (ATZ) for medical application.

To integrate 3D printing in the medical supply chain certifications are essential.

So 3DCeram has established a partnership with Gregory Nolens to carry out 3D ceramic printing in the biomedical field.

This partnership will bring the biomedical players a complete expertise and know-how to enable them when integrating a 3D printing unit in their supply chain.

On the other hand, Gregory will assist the customer equipped with a Ceramaker printer to get the unavoidable certification, dedicated to medical devices in different fields like:

3DCeram-Sinto and Grégory Nolens, with their experience and expertise, will accompany the companies, which wish to integrate 3D, in the different stages of the process, in order to integrate this new printing technology.

about the partners…

3DCeram Sinto leverages stereolithography (SLA) 3d printing technology for more than 10 years to manufacture custom-made or small series of bones ubstitutes (intervertebral cages and tibial osteotomy wedges) and cranial or jawbone implants in 2005, a study conducted in partnership with Joel Brie, surgeon at CHU Limoges to develop skull implants, from the ceramic formulation (hap) to 3D printing the implant.

Gregory Nolens, specialized in advanced manufacturing and in medical device, Gregory has a strong background in product development using innovative process for further industrial applications. Next to his Phd in biomedical sciences, Gregory has developed expertise in advanced manufacturing, management, and medical regulatory affairs. For the last years, he has founded Cerhum which has set medical 3D printed ceramic solution on the market. (Gregory is also external lecturer at university of Namur, teaching students

the innovation and realities of medical industry).

For any further information please contact : kareen.malsallez@3dceram.com – Tel. : +33 555 040 482