Among the various 3D printing processes, there is SLA (Stereolithography). At 3DCeram, it has been developed for the 3D printing of technical ceramics through a range of Ceramic 3D Printers from the

C101 EASY LAB for development and research through to prototyping, to the

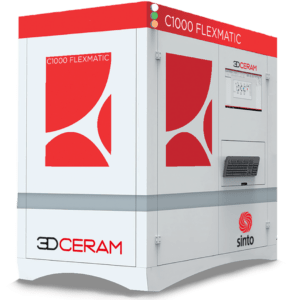

C1000 FLEXMATIC, a semi-automatic line dedicated to industrial users, and the

C3601 ULTIMATE to print large parts. This technology offers a choice of

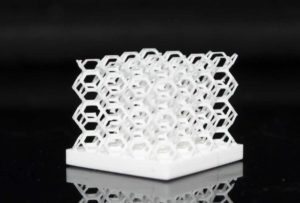

ceramic materials, to which light-sensitive resin is added. It offers the possibility of creating SLA to 3D print ceramics with customized designs, complex geometries and high precision to meet the specific requirements of professional applications.

On another hand, a 3D Printing technology, when it comes to ceramics, could be critical and that is why we have chosen to offer other technologies for 3D printing technical ceramics using an advanced extruder systems. Our solutions include filament extrusion (on the same basis as Ultimaker machine), paste extrusion, and pellet extrusion, each optimized with precision nozzle and print-head. Our desktop 3D printer, the

M.A.T., is assembled to handle various materials from spools of technical ceramics to some metals (copper, stainless steel) for fused filament. With seamless integration of STL files, our printer ensures accurate and efficient extrusion for very good quality prints.

Stereolithography technology is positioned as the solution of choice for additive manufacturing of high-quality, robust, durable parts that can withstand extreme environments (high temperatures, corrosion resistance, electrical insulation, etc.), such as satellite components, medical implants, and prototypes. With top-down lasing technology, the Z axis does not require significant height, allowing for large build platforms. This makes it an ideal printing technology for producing detailed and complex prototypes or manufactured parts in mass production. Compared with traditional manufacturing methods, SLA 3D printing offers significant advantages by optimizing design and printing processes and minimizing excess material as it is an additive way to produce. With its focus on innovation, research and industrialization, 3D-printing of technical ceramics is at the heart of the industry's evolution, offering a new way of fabrication.

Some hybrid solutions have been successfully done with hybrid printers as it was then possible to print 4 materials meantime, mainly to answer needs for electronics applications.

To ensure efficient implementation of 3D printing solutions for technical ceramics, 3DCeram offers

support and services, including

maintenance and

training on our Ceramic 3D Printers, whether in our premises in Limoges, or wherever you are. What's more, the integration of 3D printing software such as

Build-it,

CPS 2.0 and CERIA, our brand new solution of Artificial Intelligence, ensure optimal process.

This technology continues to revolutionize the industry, offering innovative solutions tailored to the needs of a constantly evolving market. From rapid-prototyping to mass production, we’ve come a long way…!