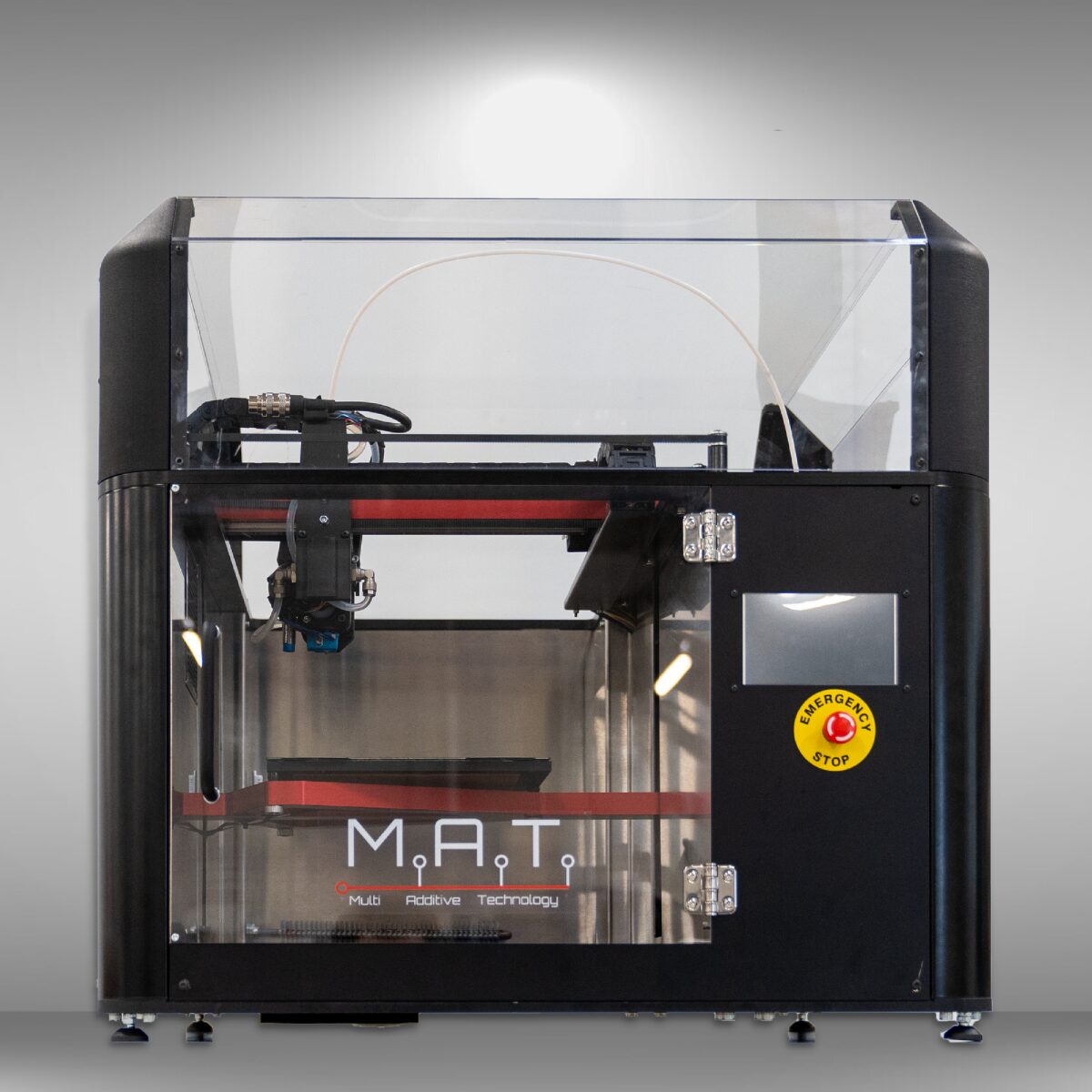

TECHNICAL DATA

• Type of printer: ............................................... Material Extrusion

• Footprint: ........................................................ 60 (W) x 60 (D) x 115 (H) cm

• Print volume: .................................................. 20 (W) x 20 (D) x 20 (H) cm

• Machine weight: ............................................. ca. 90 kg

• Supply: ............................................................ 230V, 16A, 50Hz

• Closed Loop Stepper Motors

• Heated Print Chamber (<60°C)

• Heated Filament Chamber (<50°C)